Our experience proves that even though traditional scaling (zooming) seems to be logical, easy to understand, it does not automatically produce the best results when changing the size of the wing. Indeed when using scaling the aspect ratio is preserved and kept constant, but many other parameters are not scaled correctly or not scaled at all:

1. The drag produced by pilot stays about the same through all sizes.

2. The diameter of the lines are not scaled, therefore the drag is unchanged as well as elasticity of the lines

3. The cloth thickens and the surface drag is not changed

4. Reynolds numbers are not scaled As the Air’s density and Viscosity stay unchanged.

5.And so on…

As a result when zooming, many times manufacturers have difficulties repeating handling and safety of the wing in all sizes!

It is well known that small sizes when zoomed behave more aggressively, leading to certification difficulties in the same class.

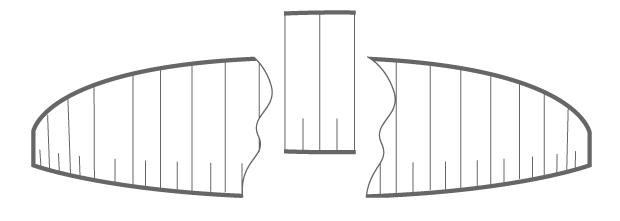

Therefore smaller wing sizes designed by APCO with lower aspect ratio and larger sizes allow to build in higher aspect which can improve performance where possible without being aggressive.

To be systematic, we at APCO on most of the wings during R&D evaluate both approaches (classic zooming and A.R.O.) and judge the final, practical result, choosing the best.

In case, as happened with Karma EVO, we achieved better result by traditional zooming – which is why we launched a glider which is zoomed and maintains same aspect ratio between S and M sizes. We did finish the design and successfully certified the Karma EVO in S and M sizes for both versions – (zoomed, with constant Aspect Ratio and APCO’s A.R.O. applied) . In the end we chose the better one – in this case the zoomed version.

In the same way when you have a wing which in our opinion gives an optimal result by using our A.R.O. system – then that is the system we use and that is the case with most of our gliders.

Also on very high aspect ratio wings – e.g. Enigma or Zefira we favor traditional approach by zooming, maintaining the same aspect ratio on each size, as on high aspect ratio wings the difference in span is too big between different sizes if we change the size by changing the span.

As you can see, we are choosing the best sizing system for each particular wing design be it A.R.O. or classic zooming.

We hope this explanation helps to explain the reason behind our approach.

Setting Future Standards

The Apco Team