Intended for :

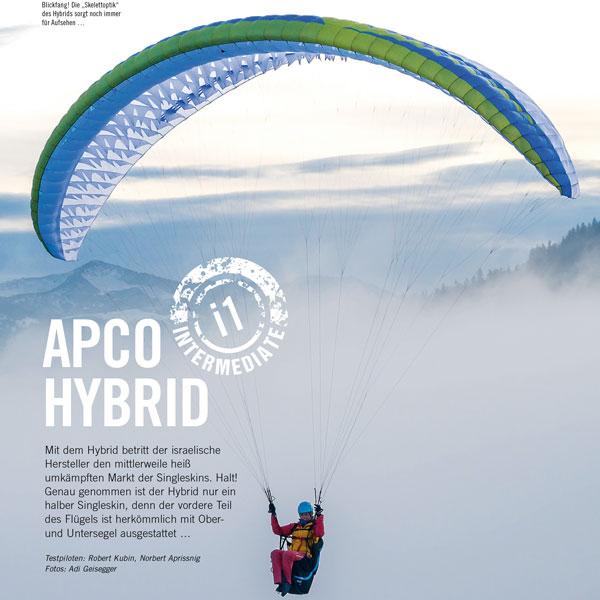

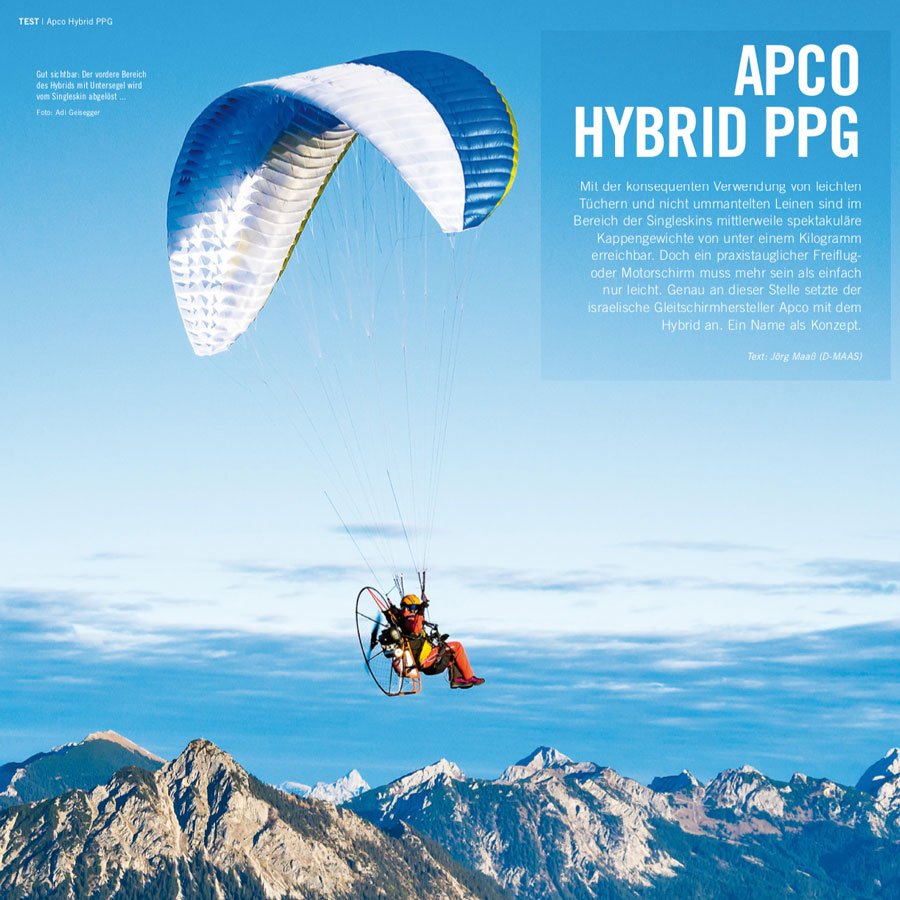

A. Schools – Front launches at no wind conditions – the Hybrid is by far the best thing there is on the market today!

B. Pilots who fly locally and do not need the wide speed range of reflex wings. Pilots having difficulties with forward launches and would like to enjoy the ease of use and slow take off speed of the hybrid.

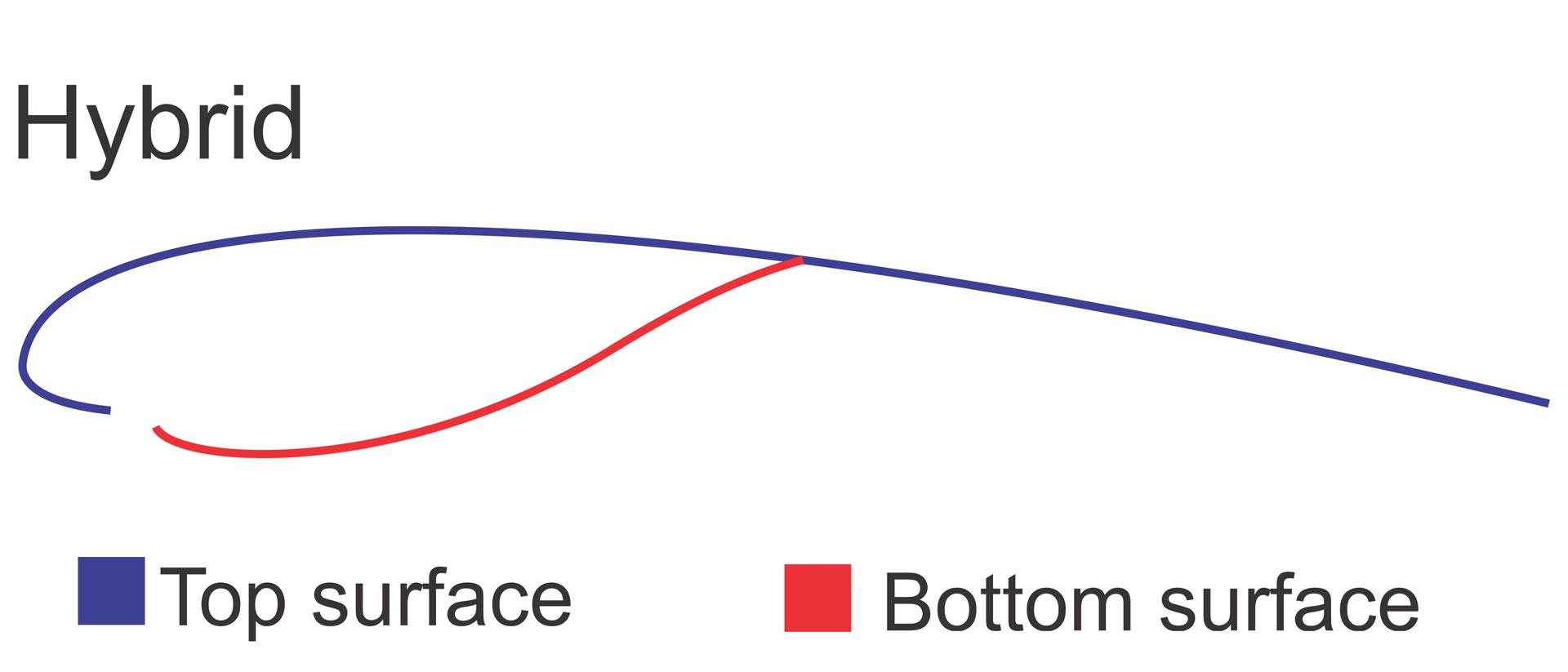

The advantages of the Hybrid for paramotor are concentrated around its stability and ease of use during take off and landing.

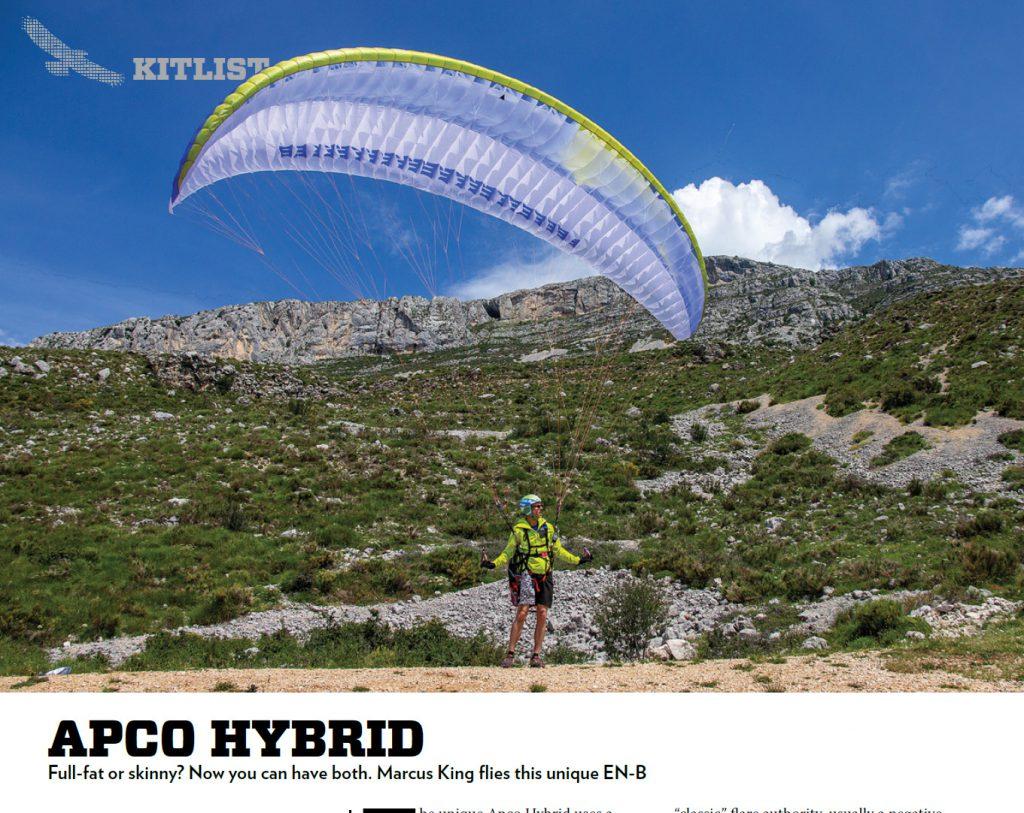

Launch – We cannot stress enough how much easier it is to foward launch and take off with this wing. There is nothing to compare it to including the Lift 2EZ.

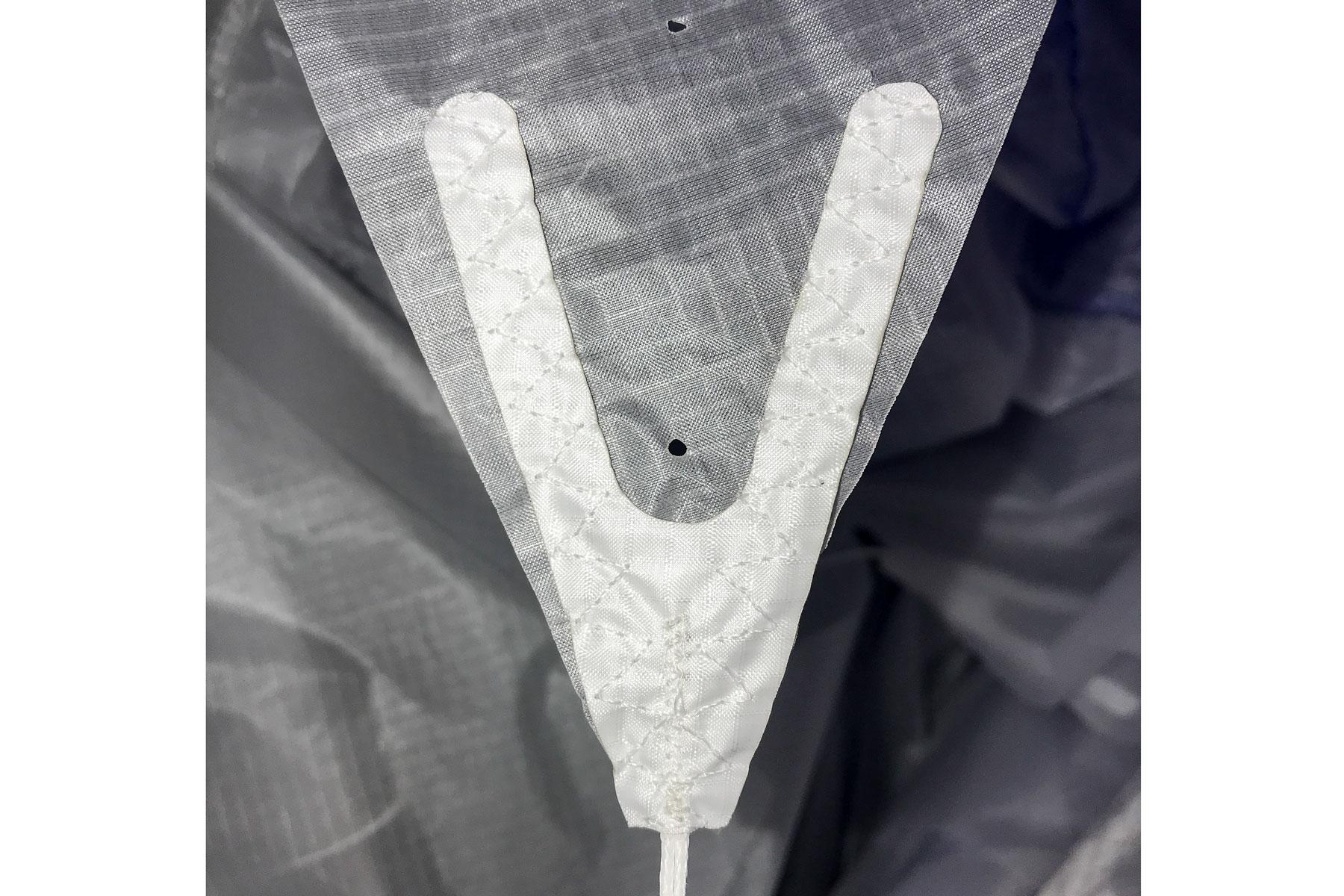

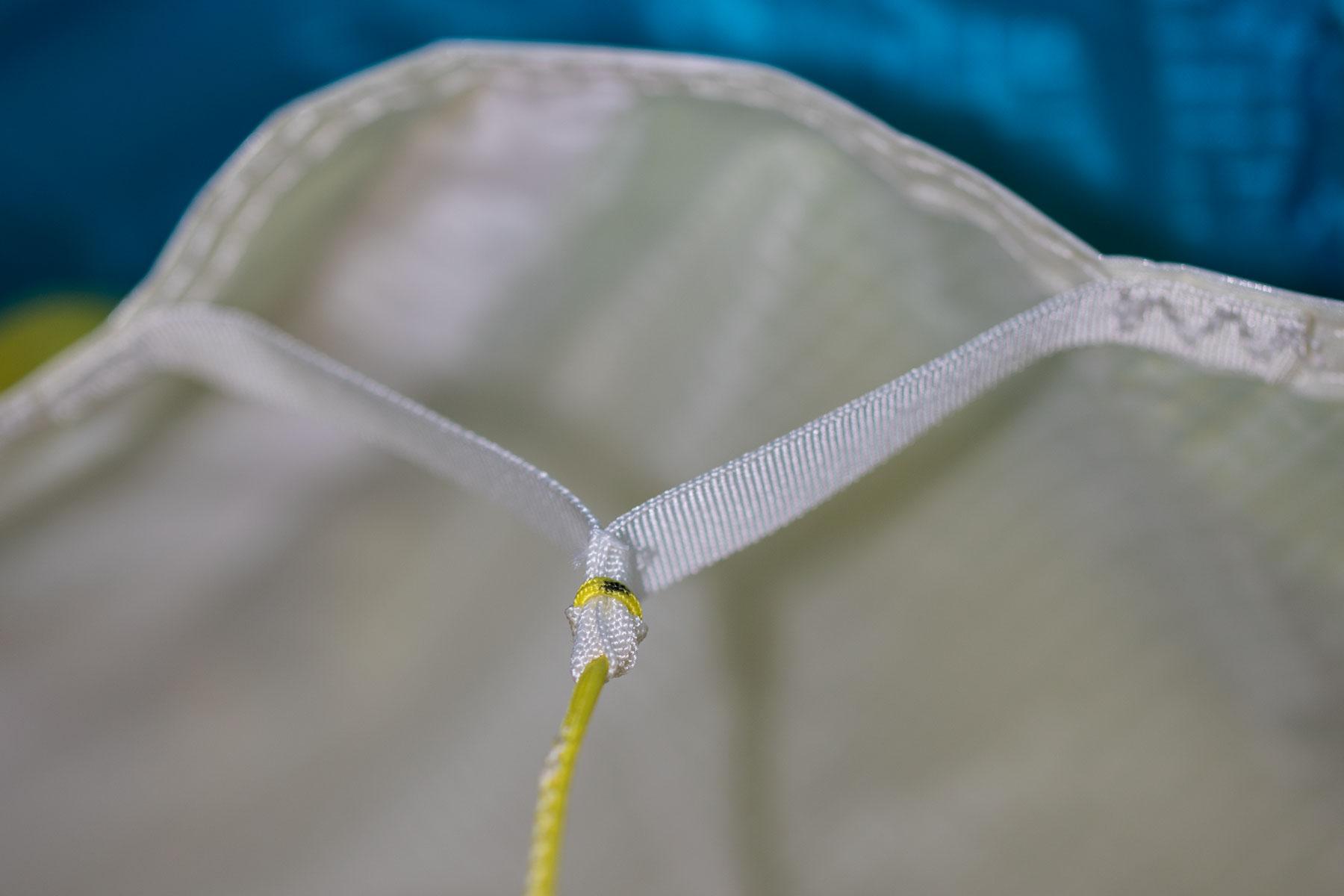

The Hybrid is not a fast wing which makes the take off run shorter and slower than other wings. The light weight canopy ensures that it comes overhead with less effort than a regular wing.

The required effort on the A-risers is lower than on a regular wing and just two or three, easy steps forward brings it overhead. The stability of the profile helps to keep it directly above the pilot. There is no tendency to roll to the sides during the take off run, the pilot hardly needs to move under the wing, as it will center itself above the pilot.

In Flight – the first thing you will notice is the low brake pressure! there is no need for tip steering (as it is not a reflex profile), and the load is lower than anything you have tried!

The second would be the roll stability – with this wing there is no roll instability (Oscillation) whatsoever! This wing would be the perfect tool for aerial photographers, not too fast and extremely stable. You can take your hands off the brakes and the wing stays as steady as a rock. There is also slight to no torque effect, as very low power is needed due to the highly efficient profile.

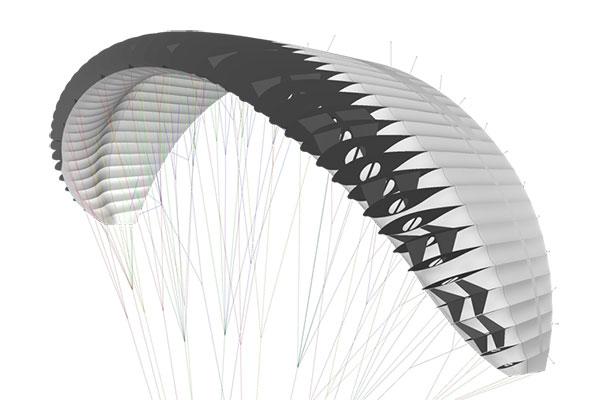

The pitch stability resembles the behavior of a reflex profile, this is noticeable mainly when ground handling.

Compared to a reflex wing the hybrid is more “sensitive”. It is a light weight wing that gives better feedback of the air to the pilot. It will move more than a reflex wing that behaves much more as a rigid structure.

The Hybrid will reverse launch in very light wind conditions, but the advantages of the Hybrid will decrease on windier days where high air speeds are needed.

For pilots that fly in lower winds this is by far the best and easiest wing there is on the market today!

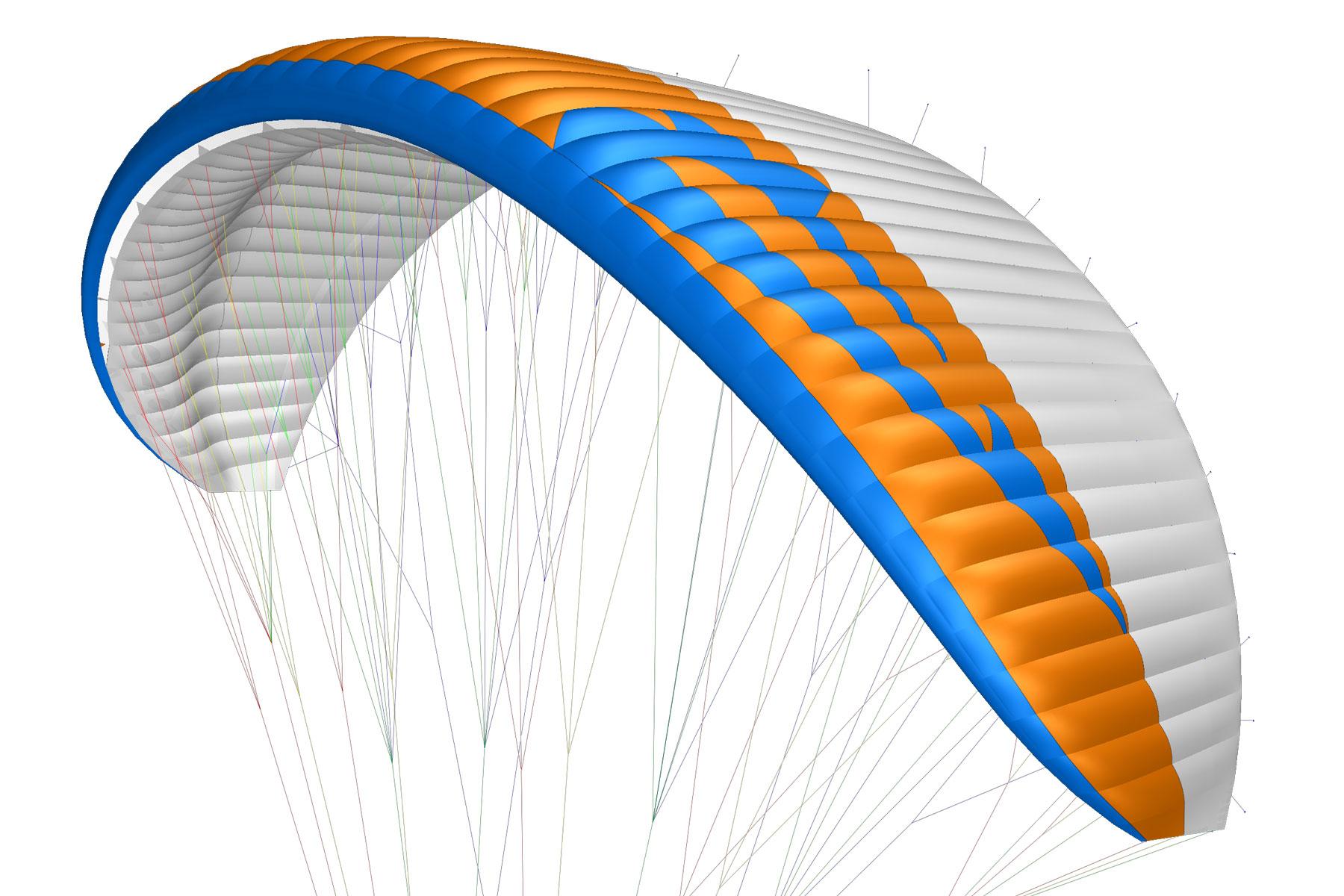

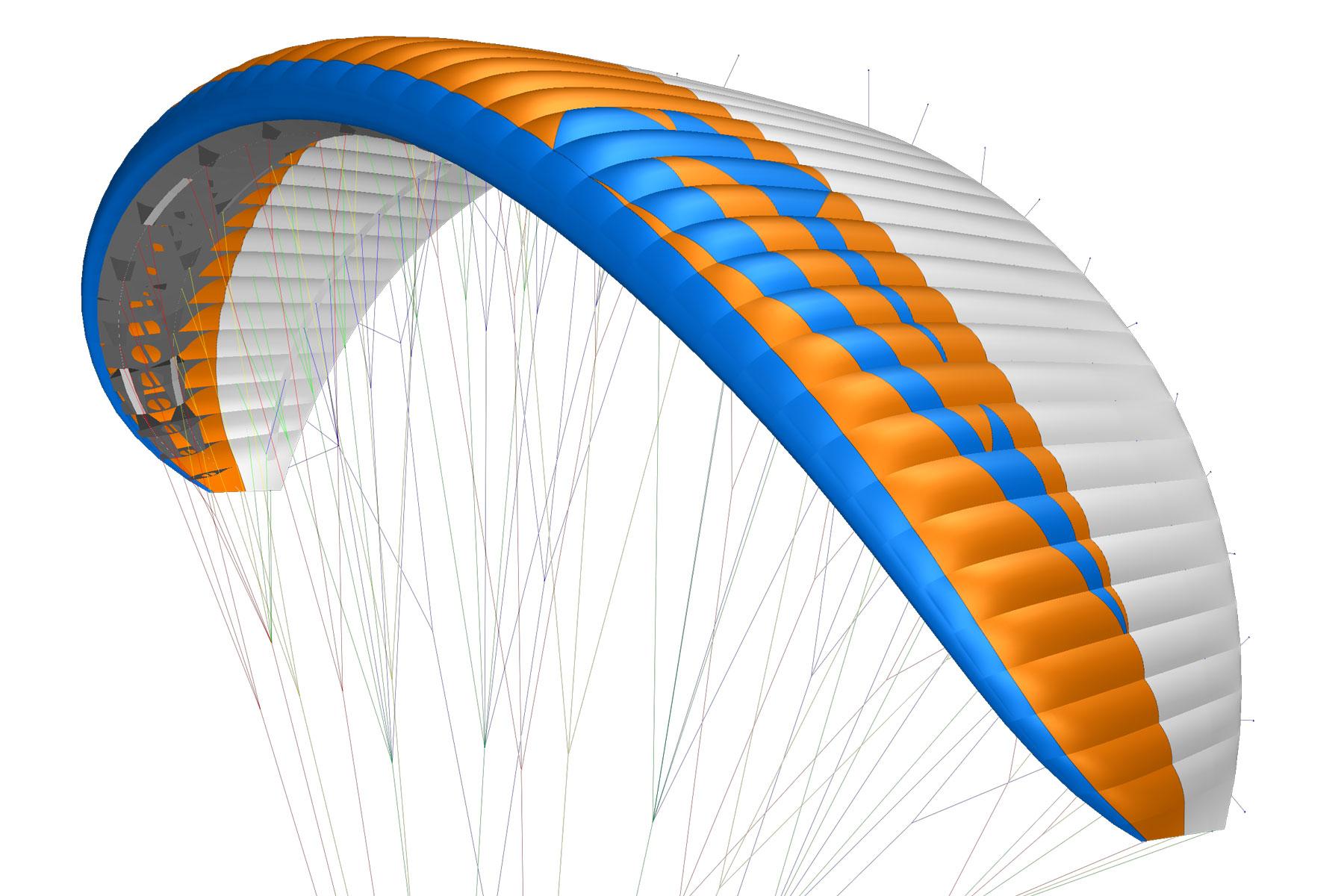

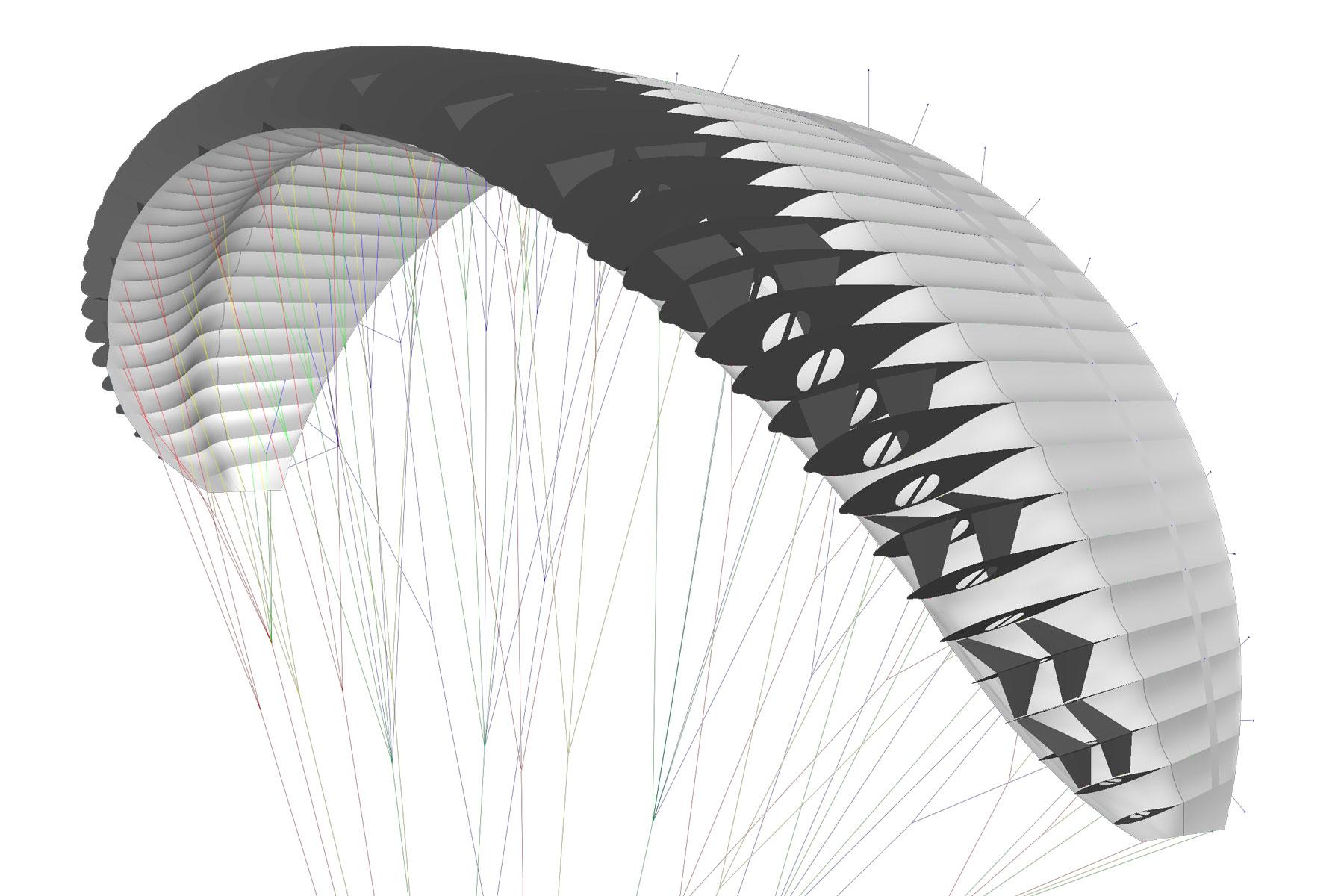

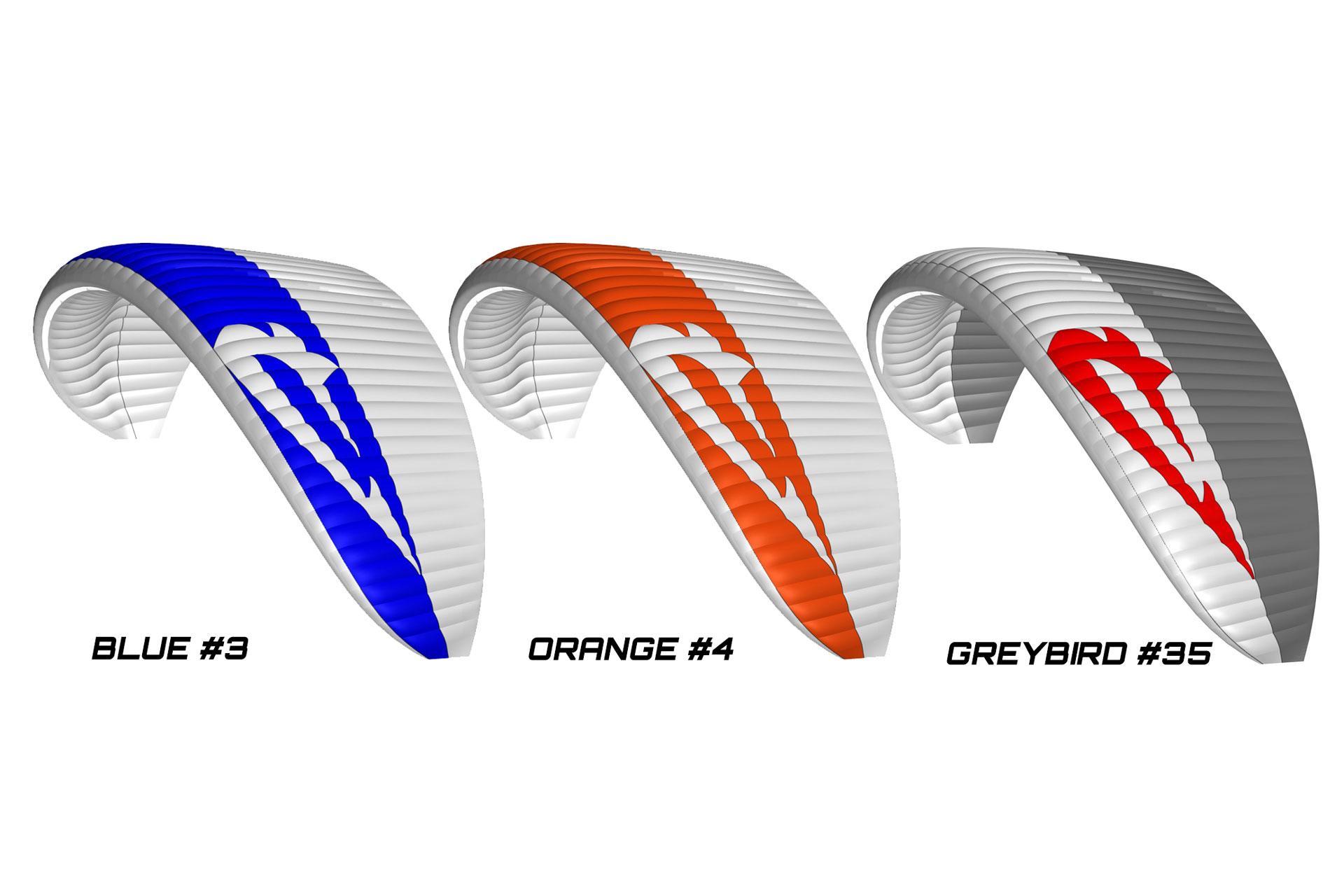

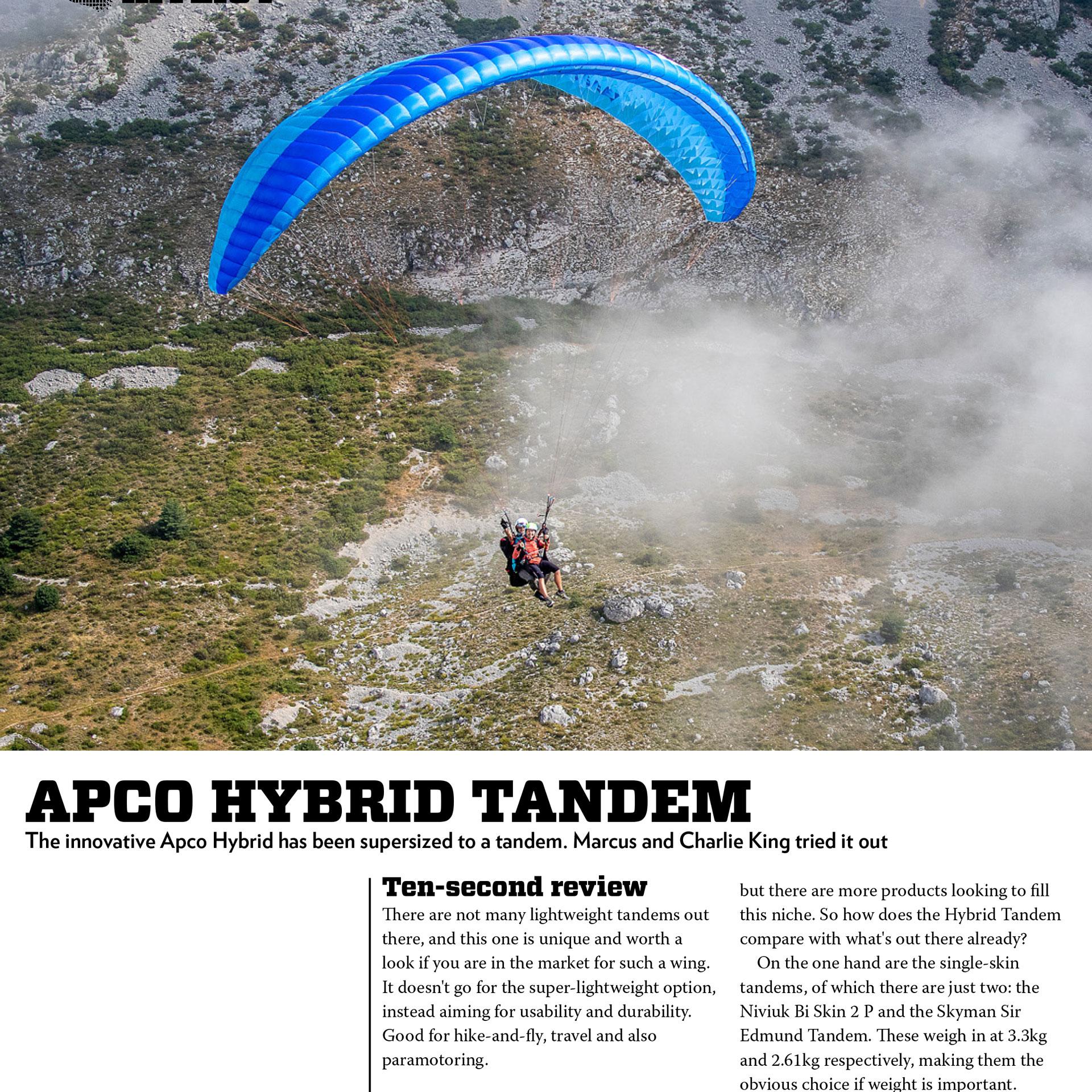

A truly revolutionary design – The APCO Hybrid.

A truly revolutionary design – The APCO Hybrid.

I have flown the Hybrid tandem this evening with my son.

I have flown the Hybrid tandem this evening with my son.