Bullet Riser 2 – a revolutionary design of a riser. (In the best APCO tradition thinking outside the box)

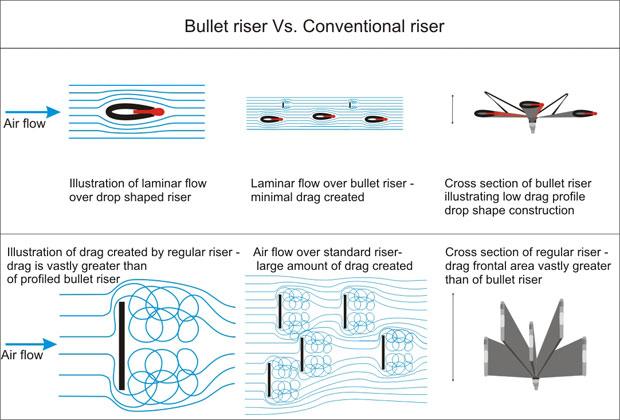

The riser which will set the future design for the industry – reduction of riser drag by 80% and more.

Its drop shaped branches produce only a fraction of the drag produced by regular risers. It is still made from the same 25mm. width webbing, but shaped into a tear drop profile – easy to understand and handle.

See the photos comparing the 2 risers and their frontal areas – on the left bullet riser, right side regular riser –

no further comments required! – A truly intelligent design.

It is a very effective way of improving performance without sacrificing safety, handling and integrity of the wing.

Instead of making risers from narrower webbing (a recent trend followed by everyone else) which leads

to a hardly noticable slight reduction of drag, we took a more innovative approach. Taking the same 25mm flat webbing riser (facing the flow against its full width – with a huge amount of drag) and transforming it into

a tear drop shape cross section, producing minimal amount of drag –

see sketch illustrating the differences.

Bullet risers are a most effective way of improving performance without sacrificing safety, handling and integrity of the wing.

Bullet risers are the latest addition to the other innovative ideas from APCO’s design house aimed at improving performance and safety, with no collateral costs (imbedded minimal drag hook-up points, partial diagonal rib construction, SRS, HIT valves, FLEXON and many more…………….)