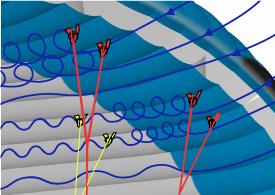

A typical glider has around 100 hook-in points, where the lines connect to its bottom surface. Each hook-in point creates a large amount of drag.

For many years APCO has been using its innovative EHP technology to reduce glider drag and improve performance.

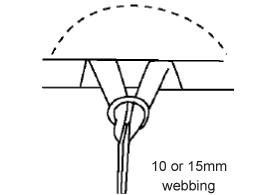

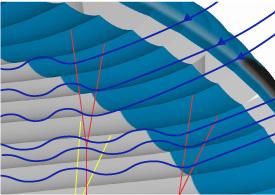

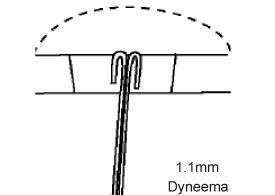

Embedding top lines directly into the bottom surface of the glider, (using APCO’s EHP technology) will significantly reduce drag on each hook-in point to the absolute minimum.

Multiplying this drag reduction over 100 line connection points results in a big performance gain.

The improvement in performance is free of any side effects and is a very efficient way to gain on L/D without sacrificing safety or handling.

Traditional hook-in points are bulky tape loops with knots around them. They act as a forest of disturbances to the airflow under the wing, each creating turbulence around itself, contributing to a thicker turbulent boundary layer at the wing’s surface and greater drag.

Embedded hook-in points offer a much cleaner interface, resulting in a thinner boundary layer and less drag. They are the most aerodynamically efficient way to connect lines to a glider. Considering that a glider has so many of them, reducing drag on each hook-in point results in dramatic performance gains. Even better, embedded hook-in points are maintenance-free and carry a lifetime warranty.

Embedded hook-up points are a proven and tested concept since it was introduced by Apco in the 90’s and used on thousands of wings.

APCO is convinced this is the right way to enhance performance.

Small improvements – great gains.

Can you please advise how we should test the strength of the upper lines on this wing? Ordinarily we'd remove an upper line and test destructively to confirm continued airworthiness. But on this wing the upper lines are sewn in, so the normal process cannot be undertaken. What do you advise?

Embedded hook up points (top lines) are Dyneema 100 kg.

They will outlast any other parameter of the wing’s construction and there is no need to check strength of the top lines – only the floors beneath require checking.